Bantuan

Berikut senarai insentif dan bantuan kerajaan terkini yang anda boleh mohon. Antaranya:

Baca juga: Login Portal ADPM KPM di sini.

Untuk maklumat lanjut, rujuk artikel-artikel di bawah.

Waktu solat dibawakan oleh taqwa.my

Dapatkan himpunan doa selepas solat hanya di Taqwa.

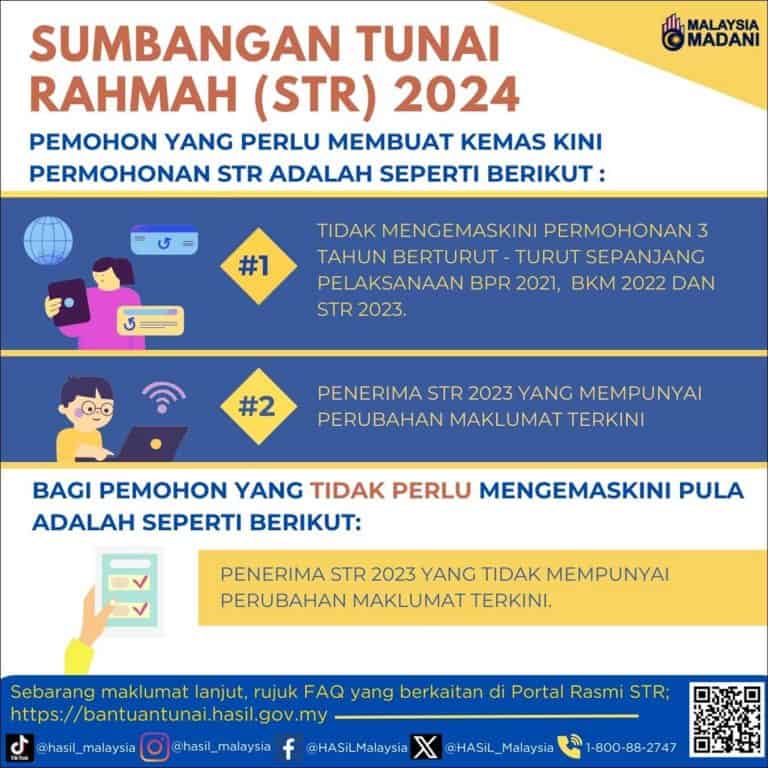

Kemaskini STR 2024 (Sumbangan Tunai Rahmah)

STR Fasa 4 : Semakan Status, Tarikh & Jumlah Bayaran (2024)

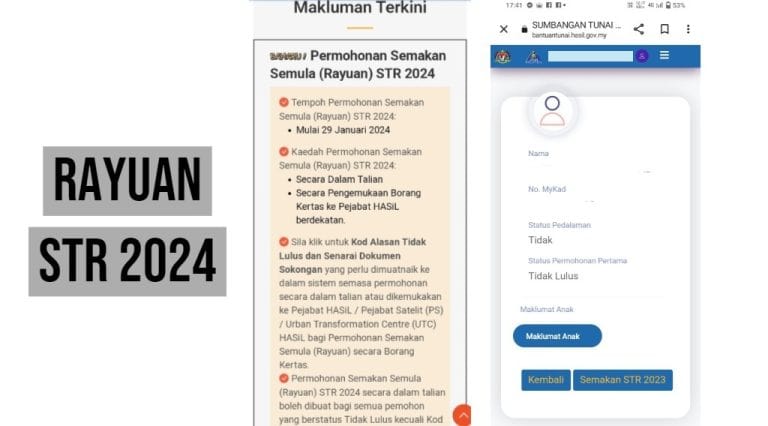

Rayuan STR 2024 – Maksud Tidak Lulus & Dokumen Permohonan

Bantuan Khas Aidilfitri 2024 Penjawat Awam & Pesara

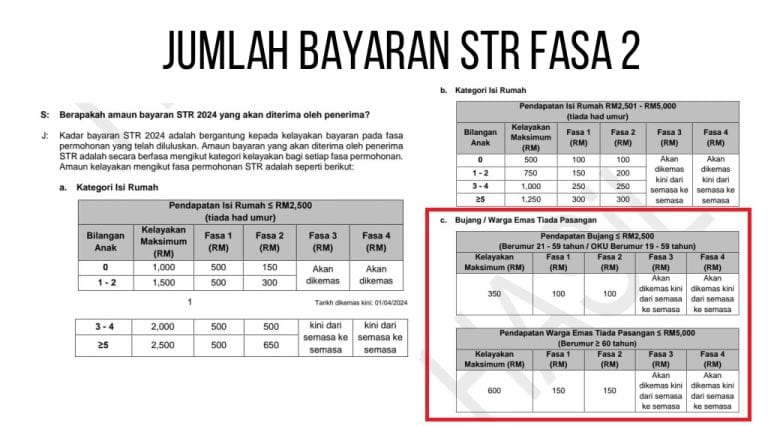

Jadual Bayaran STR 2024: Tarikh & Jumlah Bantuan Fasa 1,2,3,4

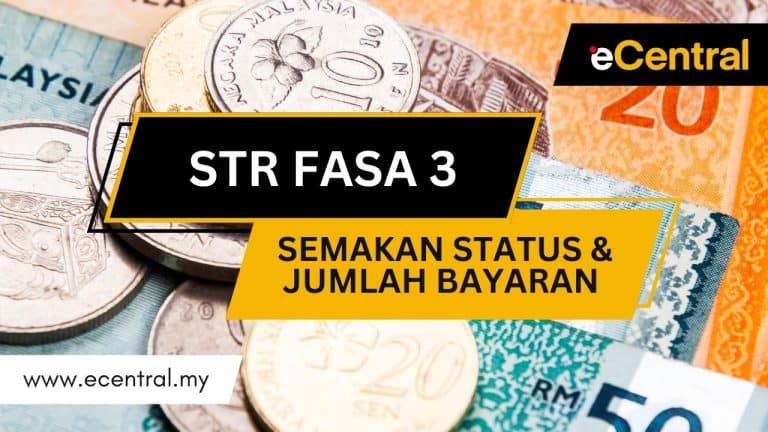

STR Fasa 3 : Semakan Status, Jadual Bayaran 2024

STR Bujang: Jumlah Bayaran Bantuan Tunai Rahmah 2024

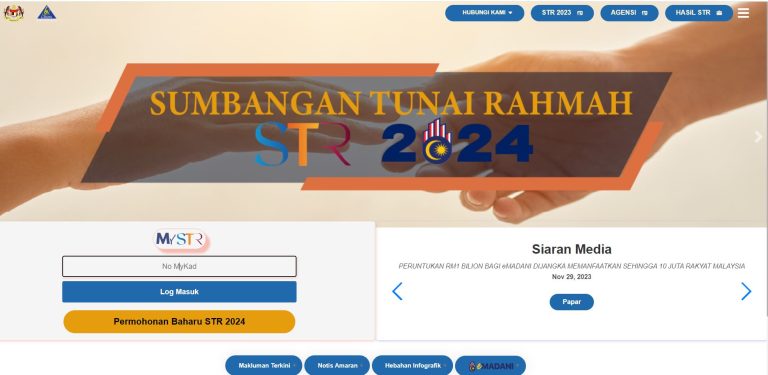

STR 2024 : Semakan Status Bayaran Sumbangan Tunai Rahmah

STR Fasa 2: Semakan Status & Jumlah Bayaran Mulai 3 April 2024